Looking to make your mail stand out? Custom printed paper envelopes with a window can do just that. Whether you’re sending out invitations, announcements, or business correspondence, these envelopes add a touch of personalization that catches the eye.

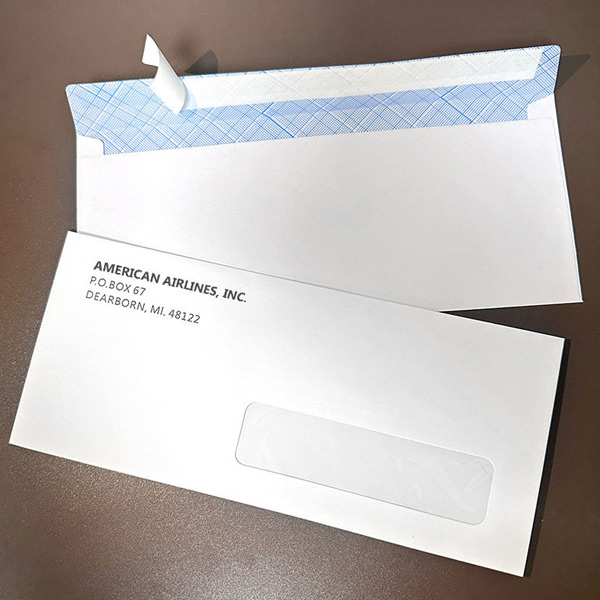

The window on the envelope allows recipients to see the contents without opening it. This feature can make your mailing more efficient and enticing. Custom printing adds another layer of distinction, showcasing your brand or message effectively.

Imagine your recipients’ curiosity when they receive an envelope with a unique design, hinting at what’s inside. This creative approach not only elevates your presentation but also communicates professionalism and attention to detail.

Benefits of Using Custom Printed Paper Envelopes with Window

Custom printed paper window envelopes provide a range of advantages, especially for businesses.

1. Brand Recognition: Using envelopes with your logo or design helps promote your brand. People recognize and remember your name more easily.

2. Professional Appearance: These envelopes appear neat and organized. This makes your mail look trustworthy and important. A window in the envelope is also useful. It shows important information like addresses without extra effort.

3. Cost-Effective: Since the window displays the address, you save time and money from printing addresses separately.

4. Eco-Friendly Option: Paper envelopes are recyclable. This quality benefits the environment and supports sustainability efforts. Communicate your commitment to eco-friendly practices through your mailing choices.

Custom window envelopes serve various practical and aesthetic purposes. They help streamline your mailing process, improve brand identity, and enhance the professional look of your communications.

Design Considerations for Custom Window Envelopes

When designing custom printed paper envelopes with a window, focus on the window’s placement, the materials and print options, and how to incorporate brand identity. Each aspect influences the envelope’s functionality and appearance.

Choosing the Right Window Placement

The window placement on an envelope is crucial for displaying its contents effectively. Consider the size and position of the window. It should reveal important parts of the document inside, like addresses or logos, without exposing sensitive information.

Try different shapes and sizes to find what works best for your needs. Standard rectangular windows are common, but circular or oval shapes can add a unique touch.

Ensure the window material is clear and durable. This keeps the contents visible while protecting them during handling. Proper placement and material choice can enhance both practicality and aesthetics.

Selecting Materials and Print Options

Choosing the right materials for your envelopes is essential. Paper thickness impacts durability and presentation. Heavier paper stock often provides a more premium feel and withstands shipping better.

Next, explore different print options. Offset and digital printing are popular choices. Offset is ideal for large quantities because it’s cost-effective. Digital printing suits smaller runs and offers quicker turnaround times.

Consider finishes like matte or gloss to enhance the envelope’s look. A well-chosen finish can make colors pop and create a polished appearance. Remember, the paper and print options should align with your budget and intended use.

Incorporating Brand Identity

Incorporating your brand identity into envelope design helps to establish a consistent and memorable image. Start with your brand colors and logo. These elements should be prominently featured to make your envelopes instantly recognizable.

Font choice is also important. Use your brand’s standard fonts for text on the envelope to maintain consistency with other materials.

Think about the tone you want to convey. Are you aiming for a playful, professional, or elegant look? This can guide your design choices. The goal is to create an envelope that not only looks good but also supports your brand’s message and values.

Printing Techniques for Paper Envelopes with Window

When printing on paper envelopes with windows, you have several techniques to choose from. Each method offers unique strengths, ensuring high-quality prints and vibrant colors. Here are the main printing techniques most suitable for this purpose: offset, digital, and flexography.

Offset Printing

Offset printing is a popular choice for custom envelopes. This method creates crisp and clear prints using metal plates and rubber blankets. The ink is transferred to the rubber blanket before printing on the envelope.

With offset printing, you achieve sharp details and vibrant colors. It’s especially efficient for large orders as it maintains quality and reduces costs per unit as the quantity increases. However, setting up the plates can take time, so it’s better suited for larger runs.

Digital Printing

In this method, digital files are directly sent to the printer, making it quick and straightforward. Digital printing offers more flexibility, ideal for smaller quantities or urgent jobs. It provides excellent color consistency with near-instant drying times.

You can easily make changes between prints, providing an edge for personalized touches. Although digital printing handles small to medium runs economically, it might not be the most cost-effective choice for massive orders. Its versatility makes it a favorite for quick-turnaround projects.

Flexography

Flexography uses flexible relief plates, making it a suitable method for printing large volumes efficiently. This technique offers rapid production speeds, making it great for high-volume orders. It also works well on various substrates.

Flexographic printing is designed for repeatability, maintaining high quality across runs. It’s particularly well-suited for basic color patterns rather than complex designs. The setup can be more extensive but pays off with long runs, providing economical pricing over time.

Sustainability in Custom Envelope Production

When creating custom envelopes, using eco-friendly materials and methods can make a big difference. Recycling, biodegradable materials, and eco-friendly production are important to ensure minimal impact on the environment.

Eco-Friendly Materials

Choosing materials that are kind to the environment is crucial. Recycled paper is a popular choice as it reduces the need for new resources. It is made from post-consumer waste.

Soy-based inks are another green option, releasing fewer toxins than traditional petroleum-based inks during production. These inks also maintain vibrant colors.

Fillers and glues made from natural ingredients help make envelopes more sustainable. This means using materials that break down easily without harming the ecosystem.

Recycling and Biodegradability

Using recyclable and biodegradable materials is key to reducing landfill waste. Encourage customers to recycle envelopes after use.

Biodegradable materials break down naturally, limiting the waste that remains in the environment. Biodegradable windows in envelopes are a great option.

The move towards recycling and biodegradability is growing. Many companies are seeking certifications, such as the FSC (Forest Stewardship Council) certification, to show their commitment.

These efforts help reduce environmental impact and create a sustainable future.

Ordering Process and Customization Service

When you are ready to order custom printed paper envelopes with windows, you will go through a series of steps. These involve customizing your order, approving a design, and ensuring production quality.

Steps to Customize Your Order

First, you will choose the size of your envelopes. Common sizes include #10, A4, and C5. Next, you will select the paper type. Some popular choices are standard white and recycled brown.

You also choose the placement and size of the window. Windows can vary in size and location based on your needs. Add custom printing such as a company logo or return address. You will provide the design files or work with a design team to create them.

Finally, approve your selections, confirm the quantity, and get a price quote. Review these before moving forward with the order.

Consultation and Design Approval

You can often consult with design experts who can give you advice on your order. They will help make sure your design fits the envelopes perfectly.

Before manufacturing, you will get a digital proof of the design. This can be a mock-up or flat design showcasing how your envelope will look. Check all details thoroughly.

If changes are necessary, this is the time to make them. Approval is critical because changes after this stage can delay production. Confirm the proof to proceed to printing.

Production and Quality Assurance

Once approved, your order goes into production. Machines and skilled operators handle the printing and assembly of the envelopes.

Final products go through a quality check to verify details like color accuracy and print alignment. This careful inspection helps ensure only high-quality products are sent to you.

Afterward, your envelopes are packed safely for delivery. Tracking information is often provided, so you know when to expect your order.